CNC Machining: Revolutionizing Modern Manufacturing

CNC Machining: Revolutionizing Modern Manufacturing

Blog Article

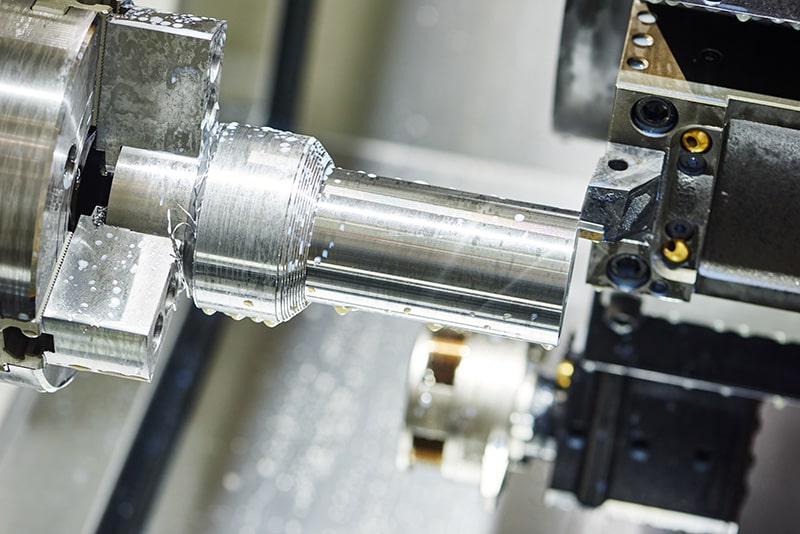

CNC-machined machining is among the most transformative technologies in modern manufacturing. It has fundamentally changed how industries produce parts and components, offering a level of high-quality, speed as well as versatility not comparable to traditional techniques. CNC machining employs computerized control and equipment to accomplish a variety of tasks such as cutting, drilling, milling, or grinding of materials that range from metals and plastics to composites and wood. Through automation of the process, CNC machining eliminates many of the inefficiencies and errors that are inherent to manual processes. The result is a system which can create highly precise components at faster speeds and in greater consistency spurring innovation in all industries, such as aerospace and consumer electronics.

At the core of CNC machine is the capability to transform digital drawings into tangible parts. Utilizing computer-aided design (CAD) software developers and engineers can design intricate 3D models of their wanted part. These digital designs are then transformed into precise directions, known as "G-code," which the CNC machine is able to follow in order to carry out processes like cutting, or milling. This control is digital, which allows for an extremely high degree of precision that manual machining could never reach. Also, once a design is programmed into the machine, it is repeatable with perfect consistency, producing identical components in huge quantities without manual adjustments. The ability to repeat is vital in industries where precision and consistent production are important.

Efficiency is another significant benefit of CNC cutting. Once the design has been integrated into the machine, it runs automatically, performing multiple operations without constant human intervention. This means faster manufacturing times as well as greater accuracy in the production of parts. Also, CNC machines can operate at a constant rate, which means that producers could produce products around continuously, which can increase overall output. In contrast to traditional machines, which need experienced machinists to control the tools, CNC machining offers a significant reduction in labor costs as well as the possibility of human error. This makes it an economical solution for high-volume production.

Also, CNC machining offers high reproducibility, assuring that each product is exactly as the design originally. This is particularly important when industries require the huge quantities of standard parts like automotive or consumer electronics. Since CNC machines adhere to programmed instructions, they're able to make hundreds, or even thousands of parts with very few variations in the quality. This uniformity not only increases the durability of the finished product, but also helps reduce production waste since less parts get rejected because of defects. Additionally, since the digital designs used in CNC machine machining are easily modified or updated, manufacturers can quickly adapt to any changes in specifications or requirements of the customer without having to invest in costly retooling or machine recalibration. To find additional information kindly look at https://www.premiumparts.com/services/cnc-machining

One of the challenges associated with CNC machining is the initial set-up cost. Investing in CNC machinery as well as the software required to operate it can be expensive, especially for smaller enterprises. But the benefits over time of CNC machine machining, such as lower cost of labor, improved production effectiveness, and improved production quality often outweigh any first investment. In addition, many firms offer CNC machine-making services to companies that do not be able to purchase their own equipment, allowing smaller manufacturers to take advantage of the technology without the upfront costs. Since the need for CNC processing continues to rise, the cost of machinery and software is predicted to reduce, making it affordable to all kinds of firms.

As a conclusion CNC machines have evolved into a vital technology in contemporary manufacturing due to its precision, efficiency, and versatility. It has altered the manner parts are produced, allowing for the creation of complex designs with a high degree of accuracy, while cutting the cost of production and the time it takes. Despite the initial investment required however, the benefits over time of CNC Machining make it an valuable tool for businesses across different industries. As technology evolves, CNC machining is likely be able to play a important role in shaping the manufacturing future, driving innovations and helping businesses to meet the needs in a global market.